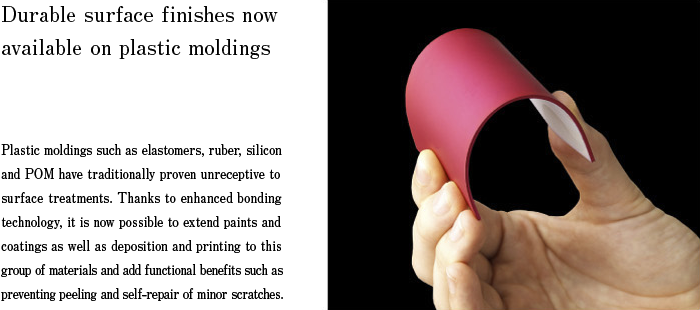

Soft plastics such as elastomers have traditionally posed a challenge for printing and coating treatments. Once removed from the mold, elastomer moldings gradually deteriorate over time due to ongoing chemical reactions with the UV and moisture in the air. We have developed a proprietary over-coating process using the revolutionary enhanced bonding technology that provides a protective barrier to protect soft plastics against natural degradation, which typically manifests as yellowing and swelling. The coating remains resolutely in place even after repeated bending and scrubbing with a brass brush. Enhanced bonding technology also works with self-repairing coatings, which have the ability to instantaneously repair scratches made with a hard object such as a brass brush.

Deposition onto soft plastics such as silicon and rubber has traditionally been plagued by difficulties with splitting and cracking. However NAKAJIMA METAL LEAF, POWDER Co. has developed a new form of deposition that bonds strongly while providing elongation of up to 150% - 200%, which allows it to withstand bending and warping. This can be complemented with a top coat for improved scratch resistance.

Plastic moldings that have been electroplated with an alloy metal other than hexavalent chromium are susceptible to oxidization in the atmosphere. Even fingerprints can cause discoloration over time, affecting shine and brilliance.

We have developed a hard coating product that provides a protective barrier to shut out moisture and gases in the air. This helps to sustain the visual appeal of electroplating for as long as possible.