NAKAJIMA METAL LEAF, POWDER Co. originally specialized in two product groups: metal powder and leaf for decorative applications, and tin foil for packaging solutions. This page describes how the company has grown and expanded through the development of new and innovative materials and applications.

NAKAJIMA METAL LEAF, POWDER Co. was founded by Sennosuke Nakajima in 1916, shortly after the end of the First World War. NAKAJIMA had been working at a trading firm, battling chronic shortages of resources in Europe and around the world. A number of major orders for pencils had come in from Russia, and NAKAJIMA was given the task of finding a domestic pencil manufacturer. He was also trying to track down gold powder and gold leaf for personalized embossing on pencils, and this provided the impetus to form a new business, a wholesaler set up for the specific purpose of supplying gold powder and gold leaf to the printing industry.

Domestically produced gold powder in those days was fairly crude, especially compared to today’s product, so NAKAJIMA decided to request samples from manufacturers in Germany. Before long, he started importing gold powder—the first Japanese supplier to do so—and selling it under the brand hakari-jirushi. The high-quality product was well received in Japan, and was quickly appropriated for other uses such as labels for canned foods and cosmetics. Demand for gold powder grew rapidly, along with demand for pure gold leaf, particularly as a decorative printing element on high-end products.

Gold powder is actually made from brass, and tends to dull more quickly than the pure gold leaf often used on works of art. It is however significantly less expensive, and is considered to have the same brilliance as pure gold. Many products that have used the cheaper substitute due to budgetary constraints have proven to be highly successful. Hot stamping foil made from gold powder is another viable substitute. The technology was not fully embraced by industry until the late 1950s, with the introduction of metallic stamping foil, described later.

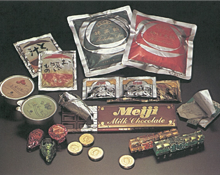

In the company’s early years, tin foil was considered one of the key products offered by a leaf-metal dealer, in the same category as metallic foil. While other products were commonly used for printing and decorative applications, tin foil was primarily used as a packaging material for foods such as chocolate, due to its flexibility and stretching properties. We sold tin foil to a number of leading confectionary manufacturers, and even began domestic production operations. But before long, there was news from Europe about a new type of foil made from aluminum, which was even lighter and easier to work than tin foil. In 1923, the first aluminum foil was imported into Japan, from Switzerland.

Aluminum was not only much cheaper than tin, it was some three times lighter and easier to process. In short, it was a far superior product, and very quickly there was strong demand for the new foil. Domestic production began in 1931, and the first domestically produced aluminum foil was launched to market in 1932.

It soon became apparent that the electrical characteristics of aluminum foil could also be put to use in electrical components. By the late 1920s, the company had developed a foil variant specifically for condensers. Production of condensers commenced shortly thereafter, and continues to this day.

Cellophane film was invented at around the same time as aluminum foil. The first cellophane film to appear in Japan was imported from France in 1924. We started importing cellophane from Italy and Germany later that year.

Gold powder, false gold leaf (made from brass) and stamping foil were increasingly accepted in the printing industry as viable alternatives to costly pure gold leaf, and demand grew steadily. Advances in aluminum foil and cellophane production technology, meanwhile, drove similar levels of growth, providing the company with a solid earnings base. It was discovered that the shielding and storage properties of aluminum could be further enhanced by combining it with other film materials and regulating the thickness. This discovery led to further growth in demand for aluminum-based long-life packaging solutions for food, pharmaceutical and cosmetic products.

Gilt tooling is commonly featured as a design element on hardcover book titles and packaging. Hot stamping foil made from gold powder has traditionally been used, although this suffers from oxidation corrosion over time (given that gold powder is actually brass powder), which diminishes the product value.

In 1953, a revolutionary new transfer deposit film was developed in Europe that used vacuum deposition to bond high-purity aluminum onto PET film. In 1954, we became the first importer to offer this exciting new product in Japan. Called metallic stamping foil (MSF), it was less prone to oxidation than brass and had a mirror-like shine, unlike gold powder. MSF was soon in great demand for books and cosmetics packaging. In 1955, we developed an automated stamping press specifically to service the burgeoning growth in this new market.

In 2006, we started supplying coil foil for in-line stamping on offset printing machines. The new product was soon in demand from the printing industry for book binding and packaging applications on offset and seal printing machines.

In 1957, NAKAJIMA METAL LEAF, POWDER Co. launched a silver paste product to capitalize on demand for aluminum powder, which had long been used as a silver decorative element. 1989 saw the invention of ink pigments based on aluminum deposit foil, boasting a mirror-like finish akin to MSF. The new ink pigments were officially launched in 1998.

In this way, we have complemented our core business of supplying metal leaf and pigment powder products with two new domains: colorful decoration of product surfaces, and flexible and functional packaging.

Globalization

Since 2014, we have been expanding our procurement network to overseas markets, in order to create cost reduction opportunities for our clients.

In 2016, we imported Pet Film from Indonesia, followed by other reliable packaging material import from Indonesia as well as China and South Korea.

In 2018, we established a local subsidiary in Shenzhen, Guangdong, China in order to expand access to overseas networks. This local business unit has been providing materials to Japanese companies in China and expanding its role as a trading company between Japan and China.

Expansion from the packaging business to cosmetics and quasi-drugs

Because of our unique flexible packaging system, which must satisfy the requirements for sensitive ingredients, our customers encouraged us to enter the filling and packaging business.

Now, we have further expanded our business from filling and packaging to full-fledged cosmetics and quasi-drugs, including ingredient supplying and planning.

In August 2018, we acquired a cosmetics/quasi-drug manufacturing and sales license.

Our first OEM product was exported to Vietnam in December 2019.

Photos courtesy of Taiyodoh Co., Ltd. and Joho Print Corporation